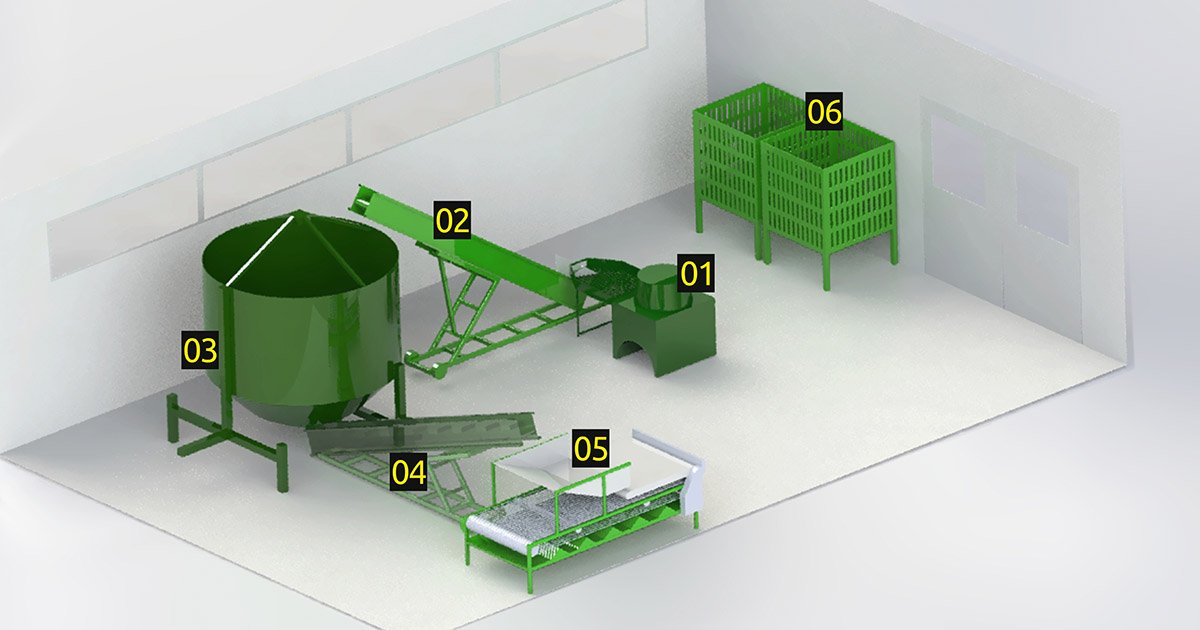

Kadıoğlu Nutmec is a sample facility set up with walnut equipment. The facility in the related image has the capacity of hulling, drying, sorting (the empty and defecting ones) and sizing 3 tons of ready-for-sale walnuts on a daily basis. One or preferably two employees are enough for the system to operate. Equipment that will be used is designated. Conveyor belt, which is numbered as 04, is preferably selected. The same system can also be operated by using a single conveyor belt.

DETAILS:

01 - Kadıoğlu Nutmec 180E Walnut Huller Machine with Sorting Table

02 - Kadıoğlu Nutmec 5 Conveyor Belt To Transport Walnuts

03 - Kadıoğlu Nutmec CKM4700E Electrically Heated Walnut Dryer

04 - Kadıoğlu Nutmec 5 Conveyor Belt To Transport Walnuts (Single conveyor which is numbered as 02, can be changed into the single conveyor belt which is numbered 04.)

05 - Kadıoğlu Nutmec CE1100 Walnut Sorting and Calibration Machine

06 - Kadıoğlu Nutmec S24 Walnut Storage Box

ADVANTAGES:

The rate of cracked walnuts of Kadıoğlu Walnut Huller Machine is a lot lower compared to the horizontal walnut huller machines. The facility is equipped with the tools that are completely compatible with each other. This system is ideal for medium or large scaled walnut businesses and it can be easily set up. You can also support the system with extra walnut hullers and dryers when required.

LIMITATIONS:

The walnut business operator should take the processes into account separately, which is necessary for fast walnut production such as packaging and transportation.

-

-